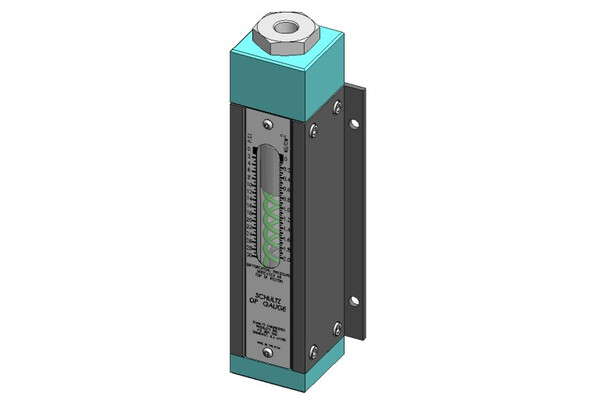

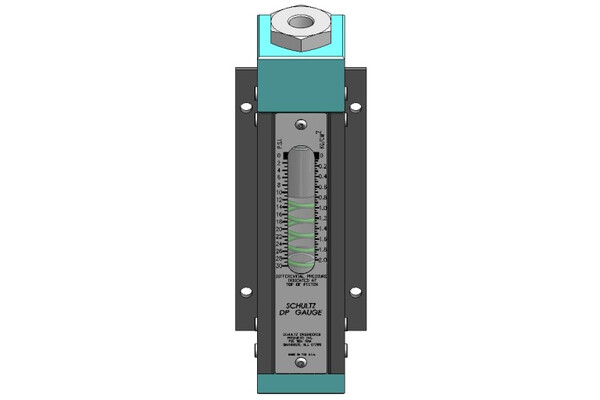

Schultz Differential Pressure Gauges

Schultz Model SC-5150 Differential pressure gauge is a direct reading piston type differential pressure indicator. It is designed to accurately and reliability read differential pressure across filter vessels. The gauge consists of a spring corrosion resistant piston moving inside an annealed glass cylinder. Differential pressure is easily read from the top of the piston.

Under normal conditions, the filter cartridges are replaced by a maintenance schedule. However, with varying conditions of fuel supply, the cartridges may need to be replaced much sooner. The differential pressure gauge gives a visual reading of the condition of the cartridges. These should be checked every time a new batch of fuel is supplied or at very regular intervals. The typical pressure for replacement is as follows:

- Filter Water Separator vessel – at 15 PSI or 100 kPa

- Microfilter vessel – at 25 PSI or 170 kPa

- Monitor vessel – at 25 PSI or 170 kPa