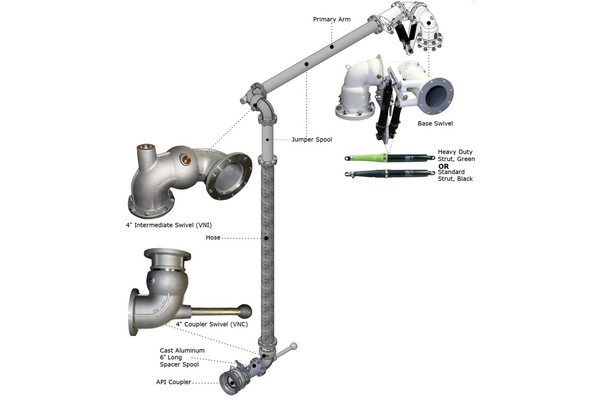

Overhead Arms

A new benchmark has been set for all bottom load arms through Liquip’s “bulletproof” overhead loading arms which provide effortless loading combined with safety, long service life and minimal maintenance.

Liquip’s 4” overhead bottom loading arms are capable of loading at flow rates of up to 2,500 litres per minute and are designed to enable complete cross-over within the API envelope of up to 6 arms in a single bay.

In regions where regulations permit, it is common to load using 3 or 4 arms at a time.

Liquip’s overhead bottom loading arms are fitted with a 2 metre standard length drop hose and varying loading arm heights are accommodated with aluminium or steel drop spools.

Standard length drop hoses enable easier changeover and reduced spare parts inventory for the operating company.

Liquip can also supply loading arm couplers that provide the connection between the tanker and loading arm that are compliant with API RP 1004.