The below technical data is an excerpt of information available and further information can be found under the resources tab.

Materials

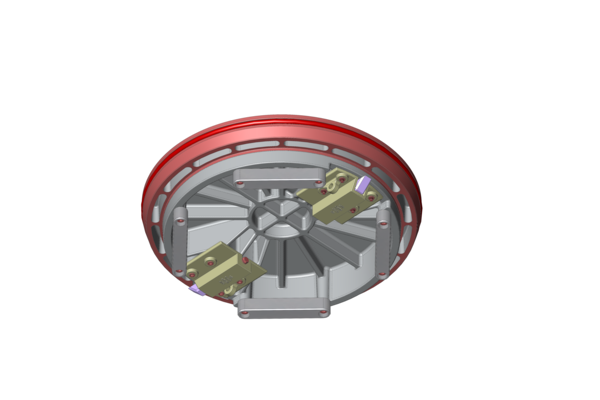

All covers and rims are cast aluminium AA601 (Heat treated & aged T6 to protect against corrosion)

All light weight fasteners are stainless steel

Plastic components nylon

Pit body HDPE (non-conductive and UV stabilized for outdoor storage)

Top seals neoprene - all other seal viton

Flanges steel to ASTM A105 or SS316 to ASTM A182

Flange fasteners ASTM A193 B7 studs with ASTM A194 2H nuts or SS 316 B8M studs & Gr8 nuts

Standards

Compliant with EI1540.

Mounting

Suitable for special 100NB flanges & 100NB pit valves. Assembly set in concrete to individual contractor requirements. To be mounted with reference to Liquip’s installation instructions.

Tether

Can be supplied with pit retaining system/tether (PRS200 suits HPA2x0 and PRS300 suits HPA1x0) to comply with JIG requirements.

Tether allows full rotation & manipulation of the lid whilst keeping it securely connected.

Bonding

Bonding kit available separately (HLC200-11).

Floor angle

Angled floor (sloped bottom).

Working Temperature Range

-40oC to +200oC.

Yield

18 MPa

Elongation

450%.

Flexural Modulus

690 MPa.

Weld neck

Entry point is designed for 100NB ANSI 150lb flange with blind threads or 150NB ANSI 300lb flange with blinds threads. These have a thick flange for improved sealing. They are fully sealed blind drilled and tapped stud holes, machine finish outside diameter and fastening point for bonding strap. The bonding strap runs from the pipe to the pit rim and is stainless steel.

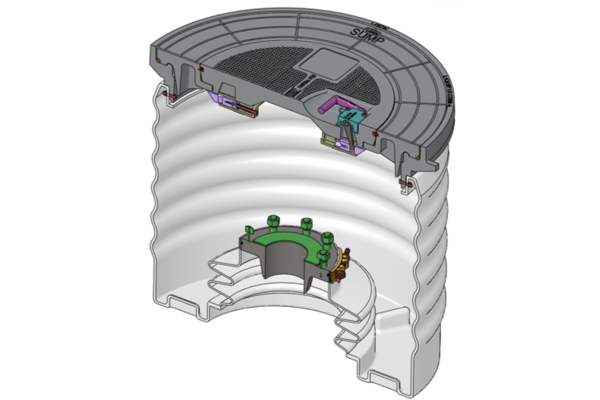

Integral Bellows

The integral moulded bellows provides seamless flexibility to accommodate the riser pipe. The 24" pit retains 45 litres before the liquid level reaches the top of the bellows. The bellows has an extended top, allowing variable installation height and surplus can be trimmed back. Entry point is designed for either a 100mm ANSI 150lb flange with blind threads or 150mm ANSI 300lb flange with blind threads.

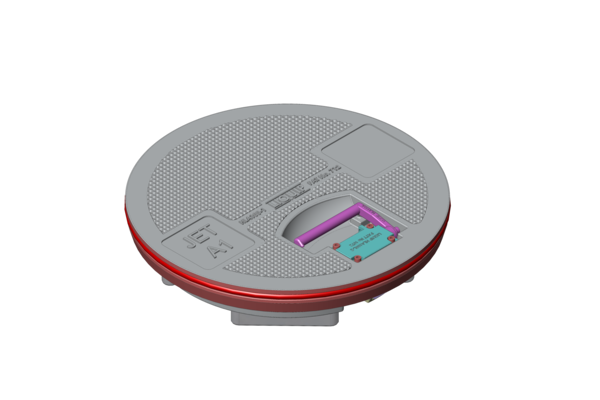

Lightweight Lid

Supplied with HLA100 as standard.

The HLA100 is the lightest pit lid on the market today which can still withstand the high forces and weights exerted by aircraft as set out in some specifications. It has an automatic self latching feature with single latch mechanism and an anti-slip top. It fits both the 18" and 24" pit.

An outer lid on the 24" lid can also easily be removed when a larger access area is required for maintenance purposes.

Operation

After installation of the pit assembly, drive your refueling vehicle to a suitable position where both the aircraft and the pit can be accessed by both hoses from the hydrant cart. With one hand lift the handle of the pit inner cover and draw towards you and the lid will de-latch, the inbuilt vacuum breaker is operated and the cover can be easily lifted free to allow access for the refueling hose adaptor from any angle. The valves are dry break and can be opened after connection of the adaptor and normal refueling operations carried out. To close the hydrant pit, slide the inner lid into place, the lid will latch under its own weight, but a light push with your foot will ensure safe connection.

Adjustment

All adjustments are made during installation. Seals and the under mount lid buffers on the pit cover should be inspected at 6 month intervals. Replace all seals and buffers as required.

Pits supplied with a removable outer cover provide a full 600mm access during valve and pipe repairs

Weight Comparisons

Conventional Steel Pit with lid, 18" = ~115kgs.

Conventional Steel Pit with lid, 24" = ~158kgs.

Conventional Al Lid = ~25kgs.

Total weight of Liquip HPA200 = ~75.5kgs.

Total weight of Liquip HPA250 = ~85kgs.

Total weight of Liquip HPA100 = ~32kgs.

Total weight of Liquip HPA150 = ~32kgs.

Hydrant Pit Body ID

| Model |

Hydrant Pit Lid OD |

Bellow Suits |

| Inner |

Outer |

| HPA100 |

18 |

- |

100 NB riser flange |

| HPA150 |

18 |

- |

150 NB riser flange |

| HPA200 |

18 |

24 |

100 NB riser flange |

| HPA250 |

18 |

24 |

150 NB riser flange |